In the world of laser cutting and engraving, precision is key. Whether you're a DIY enthusiast, a small business owner, or a professional, the laser nozzle is a critical component that can directly impact the quality and efficiency of your work. In this guide, we’ll dive into what a laser nozzle does, why it’s essential for laser cutting and engraving, and how to choose the best one for your specific needs. Understanding the value of the laser nozzle can make a significant difference in your work results and overall satisfaction.

What is a Laser Nozzle?

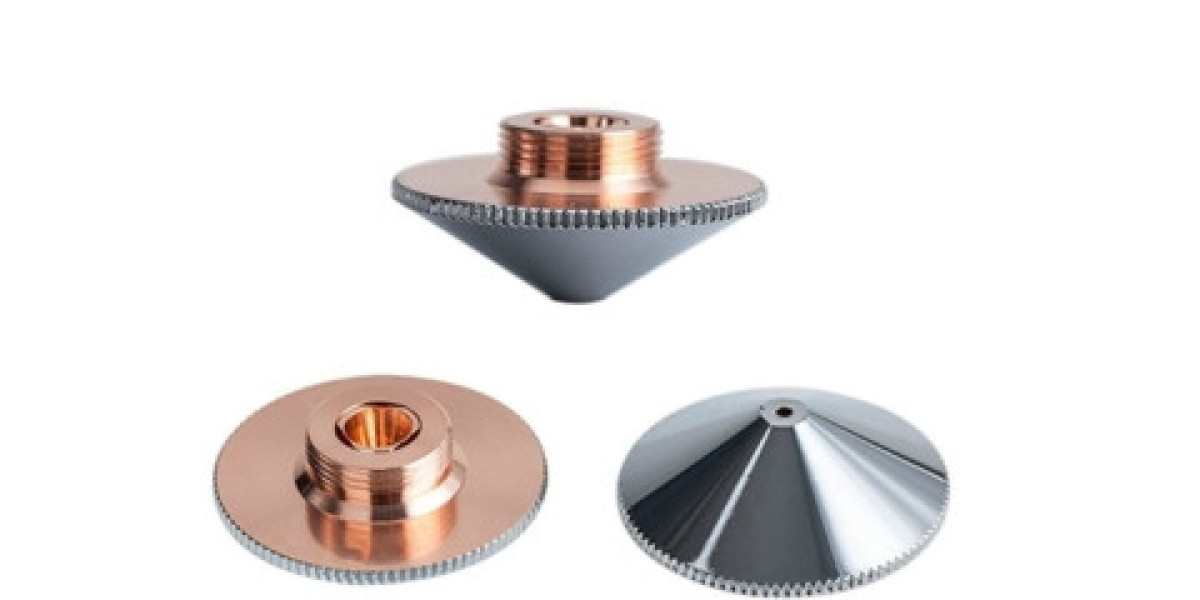

A laser nozzle is a small, but crucial component of a laser cutting or engraving machine. Positioned at the end of the laser head, the nozzle directs the laser beam to the work surface. This nozzle not only helps focus the laser energy but also facilitates efficient gas flow (such as air or nitrogen), which removes molten material during the cutting or engraving process. With the right laser nozzle, you can achieve sharper lines, cleaner cuts, and finer details, even on complex designs.

Types of Laser Nozzles

Not all laser nozzles are created equal, and each type serves a different purpose. Here are the most common types:

Single Nozzle

A single nozzle, often used for basic cuts, directs the laser beam without added gas flow. It’s ideal for tasks that don’t require intense heat dispersion or debris removal.Double Nozzle

The double nozzle is designed for higher efficiency, especially when combined with gas flow. It helps reduce excess heat and removes debris, ensuring a cleaner, more accurate cut. For industrial projects, this type of laser nozzle is highly popular.High-Precision Nozzle

As the name suggests, high-precision nozzles are tailored for delicate work, often used in industries like jewelry or electronics where intricate detailing is essential. They help in achieving extremely fine cuts and engravings without damaging the surrounding material.

Why is the Right Laser Nozzle Important?

Choosing the right laser nozzle can mean the difference between a smooth, professional finish and a project that requires multiple passes or touch-ups. Here are a few reasons why using the correct nozzle is so important:

Increased Precision

A well-matched nozzle ensures that the laser beam remains focused and stable, resulting in clean, sharp edges.Improved Efficiency

Using the right laser nozzle can reduce cutting time by ensuring smoother cuts and minimizing the need for repeat passes.Better Material Quality

By effectively removing molten material, the right nozzle prevents burns or residue build-up, maintaining the quality of your material.Longer Machine Life

Efficient gas flow prevents overheating and reduces wear on the machine, potentially extending its life and reducing maintenance costs.

Tips for Choosing the Best Laser Nozzle

Selecting the right laser nozzle depends on several factors, including the material type, project complexity, and machine specifications. Here are a few pointers to help you make the right choice:

Consider Your Material

Different materials react differently to laser cutting. Metals, for instance, may require nozzles with enhanced airflow, while plastics might need lower temperatures to avoid melting.Check the Laser Power

Higher-powered lasers often need nozzles designed for efficient heat dispersion. If your laser cutter has a high wattage, look for nozzles with good heat management features.Match Your Project Needs

For highly detailed work, invest in high-precision nozzles. For bulk cutting, such as in manufacturing, opt for durable, industrial nozzles that can handle repeated use.Test Different Nozzles

If possible, try using different nozzles on sample materials. Testing will help you see how each laser nozzle performs on specific projects, giving you a better idea of which one suits your needs best.

Maintenance Tips for Your Laser Nozzle

Keeping your laser nozzle in top condition is essential for maintaining consistent performance. Here are some quick maintenance tips:

Regular Cleaning

Dust, debris, and residue can accumulate on the nozzle, affecting laser precision. Clean it regularly to ensure maximum efficiency.Inspect for Wear

Frequent use can cause wear and tear, especially on industrial nozzles. Replace nozzles as needed to avoid reduced cutting quality.Store Properly

When not in use, keep nozzles in a safe, dry place to avoid any accidental damage or exposure to elements that might cause rust or corrosion.

Final Thoughts

The right laser nozzle is an investment in your craft, allowing you to achieve smoother cuts, cleaner engravings, and more efficient workflows. Whether you're working with metals, plastics, or delicate materials, understanding the role of your nozzle is essential for producing quality results. Take the time to choose the best laser nozzle for your machine and project needs, and you’ll find yourself enjoying sharper cuts, faster production, and a better overall experience in your laser cutting journey.