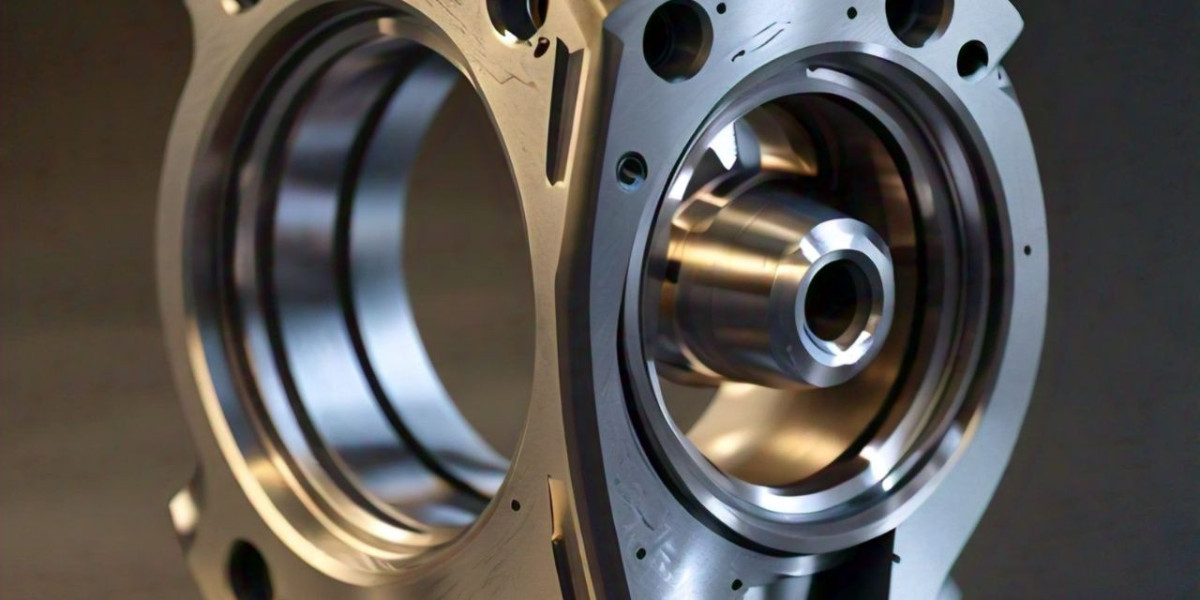

In today’s competitive landscape, precision is crucial, and custom machine parts offer significant advantages for your projects. Unlike standard components, these parts are designed specifically to meet your unique specifications, ensuring a perfect fit and optimal performance. This tailored approach enhances the overall quality of your product while minimizing the risk of costly errors and rework. By leveraging advanced machining technologies, precision custom machining manufacturers can achieve tighter tolerances and superior finishes, which are essential for high-performance applications across various industries. Additionally, custom machined parts can be produced in a wide range of materials and shapes, allowing for greater design flexibility to meet specific project requirements. This adaptability not only streamlines the production process but also empowers businesses to innovate and respond quickly to market demands. Ultimately, investing in custom machined parts enables companies to deliver exceptional results that stand out, drive customer satisfaction, and provide a competitive edge in today’s fast-paced marketplace. Embracing precision through custom solutions is a smart move for any forward-thinking organization.

What is Custom Machining?

Custom machining includes various forms of CNC machining. It refers to ordering CNC machining services to meet the specific requirements of various parts. In other words, the purpose of choosing custom machining is to create a component that meets your business goals and does not exist anywhere else. So, if you have a brand new idea or invention, or you need a part in a non-standard size, custom machining is the best option. This process allows you to create high-quality custom machined parts very quickly from a 3D CAD model, as the setup time is very short, and there are rarely any minimum order quantities involved. Additionally, custom machining offers flexibility in material selection, enabling you to choose the best option for your application. With precise control over the manufacturing process, you can achieve the exact specifications needed for optimal performance. Ultimately, custom machining is an invaluable resource for businesses looking to innovate and maintain a competitive edge in their industry. By streamlining production and reducing lead times, Custom Precision Manufacturing in the Middle East can help bring your ideas to market faster, ensuring you stay ahead of your competition. Embracing this technology can lead to significant cost savings and increased efficiency in your operations. The ability to produce custom machined parts tailored to specific needs makes Custom Precision Manufacturing a vital asset for companies aiming for success in today’s dynamic market.

Types of Custom Machining Services

Custom machining involves several manufacturing techniques, ranging from 5-axis CNC machining to metal forming. The best machining services use machines that turn, mill, drill, or last cut these techniques. CNC Precision Machining plays a crucial role in ensuring high accuracy and quality in the production of custom parts.

CNC Milling: Milling uses a rotating device to remove chips from a workpiece through physical contact and cutting. Milling techniques are used for a variety of purposes, including chamfering, grooving, and thread cutting. This allows for the creation of intricate and elaborate designs. The precision of CNC milling is unmatched with a tolerance of +/- 0.01mm. There are various subtypes of CNC machining services, including gear milling, surface milling, and form milling. The various milling processes can be used on metals such as aluminum, plastic, and steel.

CNC Turning or Lathing: CNC turning is used to manufacture cylindrical paths such as bushings and shafts. The capabilities of CNC equipment allow the cutting tool to be controlled back and forth along the side and axially while the metal part rotates. Material is removed around the metal to create the desired shape and diameter. Turning can be done on fixed-head or sliding-head CNC machines. The latter is used to reduce final manufacturing time and price.

CNC Multi-Spindle Machine: CNC multi-spindle machines have many spindles arranged inside a drum. This drum changes position and rotates horizontally to complete many operations simultaneously without the use of multiple spindles. This divides up the work so that one operation must be performed in sequence before the next to complete the selected product. Each revolution of the drum completes a part of the production. Multi-spindles make CNC machining more efficient and cost-effective than using multiple pieces of equipment. These advantages are particularly beneficial for businesses seeking Precision Machining and Fabrication Services in UAE, allowing for high productivity and precision in manufacturing processes.

CNC Laser Cutting: This manufacturing technique uses a laser beam to melt, vaporize, or remove material. CNC laser cutting often uses optics, guidance systems, and assist gases to direct the laser beam to the workpiece. After electrically exciting the laser, the beam is reflected and amplified by partial mirrors. Once it has enough energy, the laser beam is focused onto the workpiece. CNC laser cutting is fast, produces little waste, and is ideal for a wide range of materials for high-quality production.

Conclusion

Custom machined parts play a pivotal role in enhancing precision and quality in today’s manufacturing landscape. By tailoring components to meet specific project requirements, businesses can achieve optimal performance while minimizing errors and rework. The versatility of custom machining—encompassing techniques such as CNC milling, turning, and laser cutting—allows for the creation of intricate designs in various materials, ensuring that every part is made to exact specifications. This adaptability not only streamlines production but also fosters innovation, enabling companies to respond swiftly to market demands. As businesses invest in custom machining solutions, they not only enhance product quality but also gain a competitive edge that is essential for long-term success. Partnering with a certified machine shop in UAE further ensures high standards of quality and precision in every project. By embracing these advanced manufacturing capabilities, organizations can accelerate their time to market and meet the evolving needs of their customers, solidifying their position as leaders in their respective industries. Ultimately, precision and customization are key to thriving in a fast-paced marketplace.

FAQ’s

What are custom machined parts?

Custom machined parts are components specifically manufactured to meet unique specifications or designs, tailored to fit particular applications or projects.

Are there minimum order quantities?

This varies by manufacturer; some may accept small orders, while others may have minimum quantity requirements, especially for specialized components.

How do I find a reliable manufacturer?

Look for manufacturers with relevant experience, certifications, positive reviews, and a portfolio showcasing their capabilities.