Introduction

Polylactic Acid (PLA) is a biodegradable and bioactive thermoplastic derived from renewable resources like corn starch or sugarcane. With increasing awareness about environmental sustainability and the need to reduce plastic pollution, PLA has emerged as a promising alternative to traditional petroleum-based plastics. The Polylactic Acid Manufacturing Plant Project Report offers a comprehensive analysis of the steps involved in setting up a PLA production facility, covering aspects like raw materials, production process, market potential, equipment requirements, financial implications, and regulatory considerations. This article aims to provide a thorough guide for potential investors or entrepreneurs interested in entering this eco-friendly industry.

Market Overview

Growing Demand for Bioplastics

With increasing environmental regulations and consumer awareness, the demand for biodegradable plastics like PLA has risen. PLA is used in a variety of applications including packaging, textiles, agriculture, and 3D printing due to its favorable properties such as biodegradability, strength, and ease of processing.

Key drivers for the PLA market include:

- Environmental Concerns: Consumers and governments are shifting toward sustainable products to mitigate the plastic waste problem.

- Government Regulations: Many countries have introduced policies to reduce single-use plastic consumption, which has boosted demand for biodegradable alternatives.

- Applications in Various Sectors: PLA is versatile and can be used in packaging, disposable cutlery, medical implants, and more, broadening its market potential.

The global market for PLA is expected to grow at a compound annual growth rate (CAGR) of approximately 13-15% over the next decade. This creates significant opportunities for businesses venturing into PLA manufacturing.

Get a Free Sample Report with Table of Contents @

Polylactic Acid Manufacturing Process

The process of manufacturing PLA involves several stages, from sourcing raw materials to polymerization. Below is an outline of the production process:

1. Raw Material Sourcing

PLA is made from renewable plant-based resources such as corn, sugarcane, or cassava. The basic raw material is lactic acid, which is produced by fermenting these plant sugars.

2. Fermentation

The first step is the fermentation of glucose derived from corn starch or other sources. In this process, microorganisms convert the sugars into lactic acid. The quality of lactic acid plays a critical role in determining the final properties of PLA.

3. Polymerization

In the next step, the lactic acid undergoes polymerization through two main methods:

- Condensation Polymerization: In this process, lactic acid monomers are chemically bonded together, releasing water.

- Ring-Opening Polymerization: A more efficient method where lactide, a cyclic dimer of lactic acid, is polymerized using catalysts to form PLA.

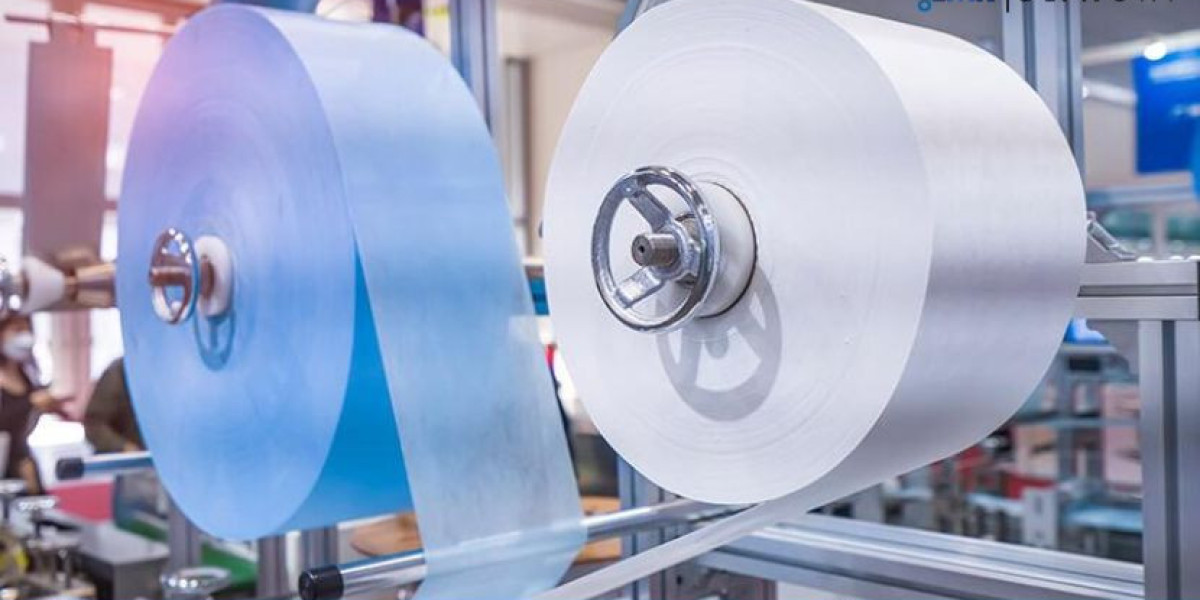

4. Processing and Forming

Once the PLA polymer is formed, it can be processed into various shapes using standard plastic processing techniques such as extrusion, injection molding, and blow molding. These processes produce PLA products such as packaging materials, containers, and fibers.

5. Quality Control

Quality testing is an essential part of PLA production. Various parameters such as tensile strength, biodegradability, thermal properties, and molecular weight are measured to ensure that the final product meets industry standards.

Equipment Required

To set up a PLA manufacturing plant, the following equipment and machinery are required:

- Fermentation Tanks: For the fermentation of plant sugars into lactic acid.

- Reactors: To facilitate the polymerization of lactic acid into PLA.

- Extrusion Machines: For shaping PLA into usable forms.

- Mixers and Blenders: To combine additives and adjust properties such as flexibility and durability.

- Cooling Systems: To control temperatures during the manufacturing process.

- Packaging Machines: For packaging the final product.

Financial Considerations

1. Capital Investment

The initial investment required for establishing a PLA manufacturing plant depends on factors such as the plant’s production capacity, location, and the type of equipment purchased. On average, the capital investment for a medium-scale PLA plant can range from $2 million to $10 million.

2. Operating Costs

Operating costs include raw material procurement, labor, energy, and equipment maintenance. Since the raw materials are derived from renewable sources, costs may fluctuate based on crop yield and market prices. Other major expenses include electricity, labor costs, and regular machine maintenance.

3. Revenue Potential

Revenue depends on the scale of production and the demand for PLA products in various sectors such as packaging, medical devices, and consumer goods. With the growing demand for eco-friendly plastics, the PLA industry offers healthy profit margins ranging from 10-20%, depending on market conditions and operational efficiency.

4. Profit Margins

PLA manufacturers typically enjoy good profit margins because of the increasing preference for biodegradable materials and the premium consumers are willing to pay for sustainable products.

Regulatory Considerations

Compliance with local and international environmental regulations is crucial when establishing a PLA manufacturing plant. These may include:

- Environmental Impact Assessments (EIA): To ensure that the plant operates in an eco-friendly manner.

- Health and Safety Regulations: Compliance with workplace safety standards.

- Biodegradability Certifications: Certification of the product as biodegradable and eco-friendly, which is often required for marketing purposes.

- Waste Disposal: Safe disposal of any by-products generated during the production process.

FAQ

1. What is Polylactic Acid (PLA)?

Polylactic Acid (PLA) is a biodegradable plastic made from renewable plant-based resources like corn starch or sugarcane. It is widely used as an eco-friendly alternative to traditional plastics.

2. What are the applications of PLA?

PLA is used in various applications, including packaging, disposable cutlery, 3D printing, textiles, and medical implants.

3. How much does it cost to set up a PLA manufacturing plant?

The capital investment for a medium-scale PLA manufacturing plant ranges between $2 million to $10 million, depending on the scale of production and equipment used.

4. What are the key raw materials used in PLA manufacturing?

The primary raw material used in PLA manufacturing is lactic acid, which is derived from the fermentation of plant sugars like corn starch or sugarcane.

5. Is PLA environmentally friendly?

Yes, PLA is biodegradable and made from renewable resources, making it an environmentally friendly alternative to conventional plastics. It decomposes under industrial composting conditions and is non-toxic.

6. What are the profit margins in the PLA manufacturing industry?

Profit margins in the PLA manufacturing industry can range from 10% to 20%, depending on production efficiency, market demand, and operating costs.

7. What are the growth prospects of the PLA market?

The global market for PLA is expected to grow significantly due to rising environmental concerns and increased demand for biodegradable plastics across various industries.

Related Reports

https://www.expertmarketresearch.com/articles/top-lead-acid-battery-for-energy-storage-manufacturers

https://www.expertmarketresearch.com/reports/india-tyre-market

https://www.expertmarketresearch.com/articles/top-mayonnaise-companies

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au