Bhansali Wire Mesh is one of the leading Wire Mesh Manufacturers in India. We offer the best quality products at a reasonable price for our customers to make their work easier and more efficient. It is also one of the leading exporters of Wire Mesh, with a focus on high-quality products.

A Brief Overview of Wire Mesh

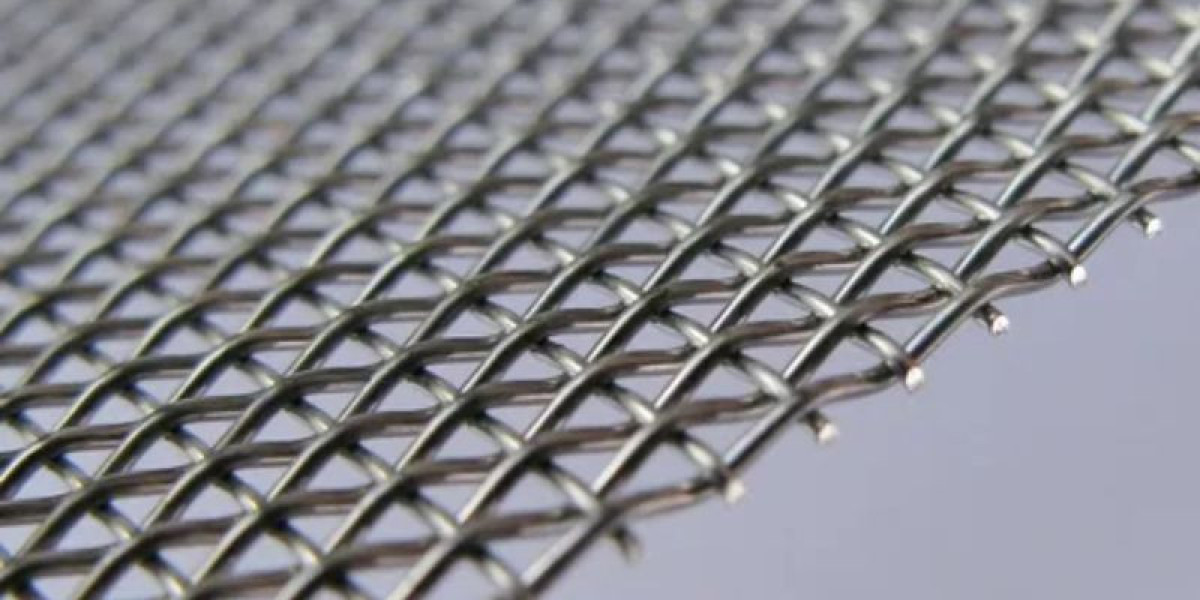

Wire mesh, also known as wire cloth or wire netting, consists of a network of intersecting wires that create a grid-like structure. This versatile material is made from a range of metals including stainless steel, galvanised steel, and aluminium. It serves numerous functions such as providing structural support, filtering, and reinforcing materials. Its adaptability makes it a crucial element in multiple industries.

The Growth of Wire Mesh Manufacturing in India

Wire Mesh Manufacturers industry has undergone significant transformation over the past decade. Once heavily reliant on traditional methods, the industry has embraced advanced technologies and innovative techniques. This shift is driven by a growing demand for high-quality, durable wire mesh products and an increasing emphasis on sustainability and efficiency.

Technological Advancements

The Indian wire mesh industry has seen significant technological advancements, which have enhanced product quality and manufacturing efficiency. Key innovations include:

Automated Production Processes: Automation has revolutionised wire mesh manufacturing by improving precision and reducing production time. Automated machines ensure consistent quality and reduce the likelihood of human error.

Advanced Materials: The use of high-grade materials, such as stainless steel and specialised alloys, has led to the production of more durable and corrosion-resistant wire mesh products. These materials are essential for applications in harsh environments.

Sustainable Practices: There is a growing emphasis on sustainability within the industry. Manufacturers are adopting eco-friendly practices such as recycling and reducing waste. This shift aligns with global trends towards environmental responsibility.

Types of Wire Mesh

Challenges and Opportunities

While the industry is thriving, it faces certain challenges. Competition among manufacturers is intense, and price sensitivity among customers can impact profit margins. Additionally, fluctuating raw material costs and regulatory changes pose challenges to manufacturers.

However, these challenges also present opportunities for growth. Companies that invest in research and development, focus on customer-centric solutions, and embrace sustainability are well-positioned to succeed. The growing demand for specialised wire mesh products in sectors like construction and infrastructure provides ample growth potential.

The Future of Wire Mesh Manufacturing in India

Looking ahead, the future of wire mesh suppliers in india appears promising. The industry is expected to continue evolving with advancements in technology and materials. Increased infrastructure development and industrialization will drive demand for high-quality wire mesh products.

Furthermore, the emphasis on sustainable practices and innovation will shape the industry's trajectory. Manufacturers who can adapt to changing market dynamics and customer needs will likely lead the way.

In conclusion, India's wire mesh supplier industry is a dynamic sector marked by growth, innovation, and opportunity. As the industry continues to advance, it will play a crucial role in supporting various applications across different sectors, contributing to the country's economic development and industrial progress.