When it comes to clean room wall panels, one of the most important aspects to consider is the core material. The core material of the panels plays a significant role in determining the overall performance and effectiveness of the clean room.

Common Core Materials in Clean Room Wall Panels

There are several different core materials that are commonly used in clean room wall panels, each with its own set of characteristics and benefits.

Gypsum Core Panels

One of the most popular core materials is gypsum. Gypsum core panels are known for their high fire resistance and sound absorption properties. They are also relatively easy to install and maintain, making them a popular choice for clean room applications.

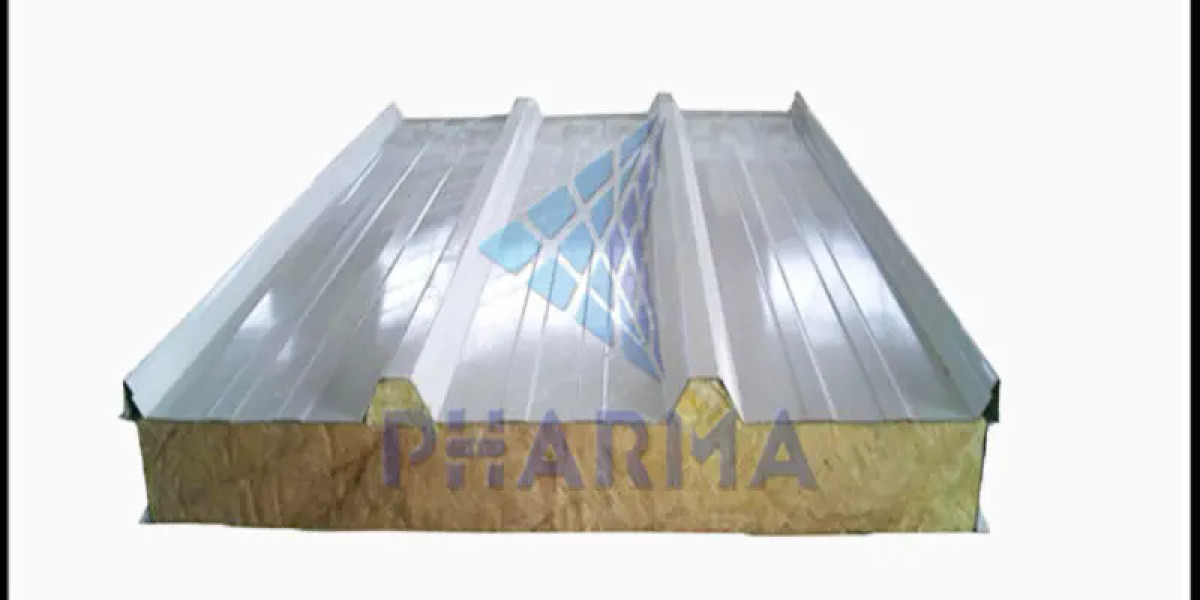

Mineral Wool Core Panels

Another common core material used in clean room wall panels is mineral wool. Mineral wool panels are known for their excellent thermal insulation properties, making them ideal for clean rooms that require temperature control. Additionally, mineral wool panels are also highly fire-resistant and provide good sound insulation, making them a versatile option for a variety of clean room applications.

Polyurethane Core Panels

Polyurethane core panels are another popular choice for clean room wall panels. Polyurethane panels offer excellent thermal insulation and energy efficiency, making them a cost-effective option for clean room environments. Polyurethane panels are also lightweight and easy to handle, making them ideal for rapid installation and renovation projects.

Other Core Materials

In addition to gypsum, mineral wool, and polyurethane core panels, there are other core materials available for clean room wall panels, such as aluminum honeycomb and polystyrene. Aluminum honeycomb core panels are extremely lightweight and offer high structural strength, making them ideal for clean rooms that require a strong yet lightweight solution. Polystyrene core panels are known for their high thermal insulation properties and moisture resistance, making them suitable for clean rooms that require temperature and humidity control.

Factors to Consider When Selecting Core Materials

When selecting a core material for clean room wall panels, it is important to consider the specific requirements of the clean room environment. Factors such as fire resistance, thermal insulation, sound absorption, and structural strength should all be taken into account when choosing a core material. Additionally, it is important to consider the installation process and maintenance requirements of the panels, as some core materials may require specialized installation techniques or ongoing maintenance to ensure optimal performance.

Conclusion

In conclusion, the choice of core material for clean room wall panels plays a crucial role in determining the overall performance and effectiveness of the clean room. By understanding the characteristics and benefits of different core materials, you can select the most suitable option for your clean room environment. Whether you choose gypsum, mineral wool, polyurethane, aluminum honeycomb, or polystyrene core panels, each material offers unique advantages that can help you create a safe, efficient, and productive clean room environment.