High suction water pumps play a crucial role in various industries and residential applications. Whether you need to move water efficiently from a deep well, remove excess water during flooding, or supply water to an irrigation system, these pumps are your go-to solution. In this blog, we will explore what high suction water pumps are, their benefits, applications, and how to choose the right one for your needs.

What Are High Suction Water Pumps?

High suction water pumps are designed to lift and transport water from deep or distant sources with exceptional efficiency. Unlike standard water pumps, these devices can create a strong vacuum that allows them to draw water from depths or handle significant vertical lift challenges. They are ideal for situations where water needs to be moved quickly and reliably from hard-to-reach locations.

Benefits of High Suction Water Pumps

Using a high suction water pump offers numerous advantages, making them an indispensable tool for various applications. Here are the key benefits:

1. High Efficiency

These pumps can move large volumes of water with minimal energy consumption. This efficiency makes them cost-effective and environmentally friendly.

2. Versatility

High suction water pumps are suitable for a wide range of applications, from residential use to industrial operations. They can handle clean water, wastewater, and even water with debris, depending on the pump model.

3. Reliable Performance

Thanks to their robust construction, these pumps perform consistently under demanding conditions. They are designed to handle high workloads without compromising durability.

4. Easy Installation and Maintenance

Most high suction pumps are user-friendly, allowing for straightforward installation and maintenance. This reduces downtime and ensures a longer lifespan for the equipment.

5. Capability to Handle Depths

These pumps excel at lifting water from significant depths, making them ideal for deep wells, boreholes, and other challenging scenarios.

Applications of High Suction Water Pumps

High suction water pumps serve a wide variety of purposes. Here are some common applications:

1. Agriculture and Irrigation

Farmers use these pumps to draw water from wells, rivers, or reservoirs to irrigate crops. Their high suction capability ensures consistent water supply, even in areas with deep water sources.

2. Flood Control and Drainage

During floods or heavy rains, high suction water pumps help remove excess water from basements, construction sites, or agricultural fields. Their ability to handle large volumes of water quickly makes them essential for disaster management.

3. Industrial Applications

Industries use these pumps to manage water supply for processes, cooling systems, and waste management. High suction pumps are also employed in mining operations to dewater pits and tunnels.

4. Residential Use

In homes, these pumps are used for tasks such as drawing water from wells, boosting water pressure, or draining water from swimming pools and tanks.

5. Municipal Services

Municipalities rely on high suction water pumps for water supply distribution, wastewater treatment, and fire-fighting operations.

Types of High Suction Water Pumps

Understanding the different types of high suction water pumps can help you select the right one for your specific needs. Here are the main types:

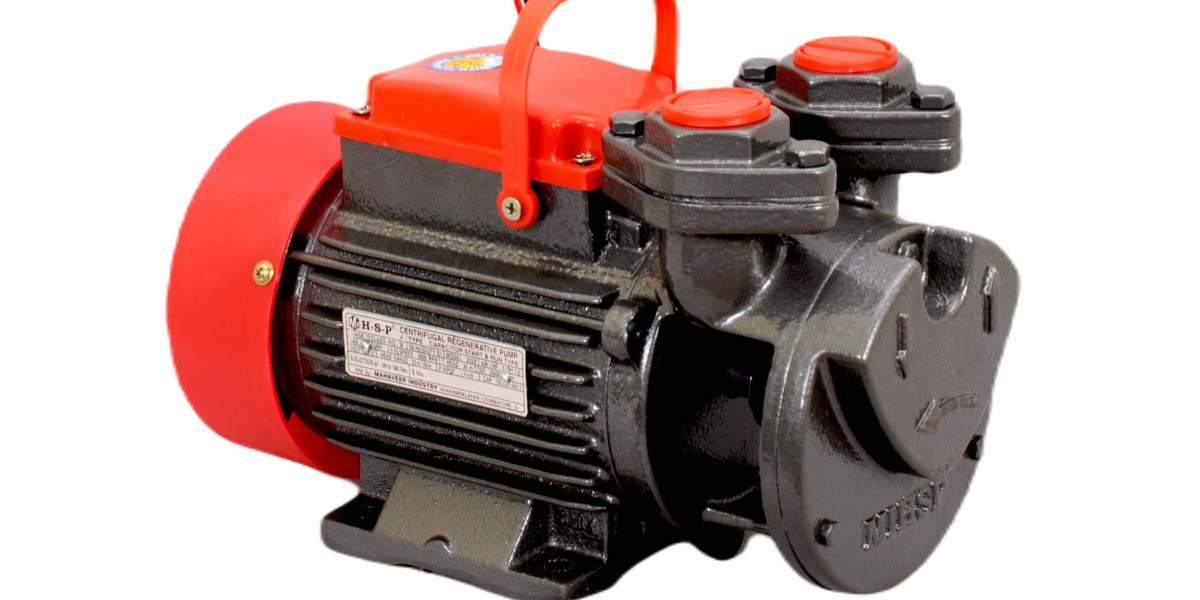

1. Centrifugal Pumps

These are the most common type, suitable for moving large volumes of water. They work best with clean water and are widely used in agriculture and municipal services.

2. Submersible Pumps

Designed to operate underwater, submersible pumps are ideal for deep wells, boreholes, and drainage applications. They are highly efficient and can handle significant depths.

3. Jet Pumps

Jet pumps combine suction power with pressure delivery, making them suitable for drawing water from deep wells. They are commonly used in residential and agricultural settings.

4. Diaphragm Pumps

These pumps are perfect for handling water with debris or contaminants. They are often used in construction, mining, and flood management.

5. Positive Displacement Pumps

These pumps are suitable for applications requiring precise water movement, such as industrial processes and chemical plants.

How to Choose the Right High Suction Water Pump

Selecting the right pump can be overwhelming, especially with so many options available. Here are some key factors to consider:

1. Flow Rate

Determine how much water you need to move. The flow rate, measured in liters per minute (LPM) or gallons per minute (GPM), should match your requirements.

2. Suction Lift and Head

Evaluate the suction lift (vertical distance the pump can draw water) and the total head (maximum height the pump can deliver water). Choose a pump that meets your depth and height requirements.

3. Power Source

High suction water pumps are available in electric, diesel, and petrol-powered models. Choose one that suits your operational environment and energy availability.

4. Type of Water

Consider the type of water you will be handling. For clean water, a centrifugal pump may suffice. If dealing with debris or sludge, opt for a diaphragm or submersible pump.

5. Durability and Build Quality

Invest in a pump made of durable materials such as stainless steel or cast iron to ensure longevity and reliability.

6. Budget and Maintenance Costs

Factor in the initial cost, operating expenses, and maintenance requirements. A more expensive pump with lower running costs may save you money in the long run.

Tips for Maintaining High Suction Water Pumps

Proper maintenance is essential to keep your pump running efficiently. Follow these tips to extend its lifespan:

Regular Inspection: Check for wear and tear, leaks, and unusual noises. Address issues promptly to prevent further damage.

Clean the Pump: Remove debris and sediment regularly, especially if used in dirty water.

Lubricate Moving Parts: Ensure bearings and other components are well-lubricated to reduce friction and wear.

Replace Worn Parts: Replace seals, impellers, and other worn components to maintain optimal performance.

Store Properly: If not in use for an extended period, store the pump in a dry, clean place and follow manufacturer guidelines.

Conclusion

High suction water pumps are invaluable tools for a wide range of applications, from agriculture to industrial operations. By understanding their benefits, types, and selection criteria, you can choose the perfect pump for your needs. With proper maintenance, these pumps will provide reliable and efficient service for years to come.