The latest report by Syndicated Analytics titled “Isobutanol Production Cost Analysis 2024 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Operating Cost, and Revenue Statistics” provides the necessary information needed to enter the isobutanol industry. Based on the most recent economic data, the study provides in-depth insights into pricing, margins, utility expenses, operating costs, capital investments, raw material requirements, and basic process flow.

The techno-economic report offers the latest information about the value-chain and demand-supply scenario. The data is collated after consulting various isobutanol manufacturers, distributors, and suppliers dispersed across the local and international markets. The study is a must-read for new entrants, investors, researchers, consultants, and company strategists. It will help them better comprehend the isobutanol industry dynamics and make data-backed business decisions.

Key aspects analyzed in this report.

Market Coverages

- Market Insights

- Impact of COVID-19

- Regional Insights

- Key Players

- Price Trends

Production Cost Analysis Insights

- Mass Balance and Raw Material Requirements

- Various Types of Unit Operations Involved

- Raw Material Costs

- Utility Costs

- Labor Costs

- Packaging Costs

- Transportation Costs

- Land and Construction Costs

- Machinery Costs

- Profit Margins

- Product Pricing

Key Trends and Drivers:

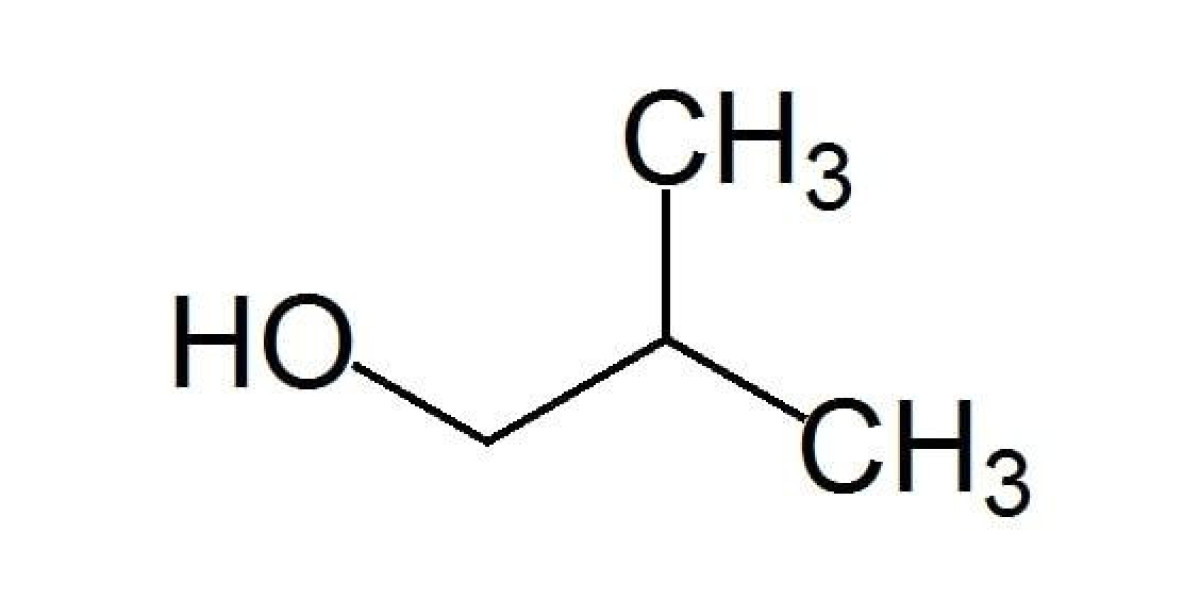

Isobutanol is a chemical compound that falls under the category of alcohol and is used predominantly as a solvent in various industrial applications. It is a colorless, flammable liquid with a characteristic odor often derived from petrochemical or renewable resources. Isobutanol is commonly utilized in the production of isobutyl acetate, which serves as a solvent in the manufacturing of coatings and paints. It is also used as an additive in fuels and in the synthesis of pharmaceuticals, polymers, and other chemical products. The compound offers a higher boiling point and lower volatility compared to other types of alcohol, making it suitable for specific formulations that require such attributes. The versatility of isobutanol has made it an essential component in diverse sectors, including automotive, pharmaceutical, cosmetics, and construction.

About Industry

The diverse application range of isobutanol that spans from the production of resins and coatings to its utilization in the pharmaceutical industry for drug formulation is one of the major factors contributing to the market growth. In addition to this, the rising demand in the automotive sector for bio-based isobutanol, particularly as a sustainable fuel additive, is providing a thrust to the market growth. Furthermore, the development and adoption of green chemistry principles, resulting in the advent of eco-friendly production processes, is creating a positive outlook for the market growth. In line with this, the increasing focus by manufacturers on sustainability, prompting the widespread adoption of renewable sources like biomass for isobutanol production, is providing an impetus to the market growth. Furthermore, the rising popularity of customization in multiple industries, from automotive to cosmetics, leading to the adoption of isobutanol as customized products require specialized formulations, providing remunerative growth opportunities for the market growth.

Request for a Sample Copy Of This Report: https://bit.ly/4bGBQDz

Report Details:

- Product: Isobutanol

- Market Size Estimation: 2024-2029

- Base Year: 2023

- Forecast Year: 2024-2029

- Process Flow Analysis: This includes an examination of the steps involved in unit operations, adherence to quality standards, conducting technical evaluations, balancing of mass, and determining the necessities for raw materials.

- Site Selection and Development: This section covers the criteria for choosing a suitable location, the importance of site analysis, strategic project planning, phased development, the environmental implications, and the associated land requirements and expenses.

- Design of Plant Layout: It focuses on the significance and fundamental requirements of plant layout, the elements that influence its design, and the overall arrangement.

- Equipment for Plant Operations: This entails detailing the necessary machinery, the financial outlay for such equipment, and information on suppliers, available upon request.

- Materials for Production: It covers the specifications for raw materials, details on procurement, associated costs, and supplier information, provided as needed.

- Packaging Considerations: This includes the requirements for packaging, information on sourcing packaging materials, the costs involved, and supplier details, available upon request.

- Additional Requirements and Expenditures: This section addresses the needs and costs related to transportation, utilities, energy, water, and human resources.

- Economic Aspects of the Project: This section analyzes capital investment, technical-economic parameters, projections of revenue and expenses, product pricing strategies, profit margins, tax considerations, and depreciation factors.

- Financial Assessment: This includes analyses of liquidity, profitability, payback period, net present value, internal rate of return, profit and loss statements, along with evaluations of uncertainty, sensitivity, and broader economic factors.

- Comprehensive Market Analysis: The report delves into market trends, segmentation, regional breakdown, price dynamics, competitive and regulatory landscapes, strategic recommendations, and case studies of successful ventures.

Browse the complete production cost analysis report with TOC and a list of figures & tables: https://www.syndicatedanalytics.com/isobutanol-production-cost-analysis-report

Key questions answered in this report:

1. What is the current scenario of the isobutanol market?

2. What is the historical performance of the isobutanol market?

3. What are the major market trends in the isobutanol industry?

4. What are the growth prospects and opportunities in the isobutanol market?

5. What are the key market segments in the isobutanol industry?

6. What is the isobutanol manufacturing process?

7. What are the mass balance and raw material requirements for isobutanol production?

8. What are the price trends of the raw materials required?

9. What are the utility costs involved in isobutanol manufacturing/production?

10. What are the operating costs involved in isobutanol manufacturing/production?

11. What are the various costs related to isobutanol production/manufacturing?

12. What are the investment opportunities in the isobutanol market?

13. What are the machinery requirements for isobutanol manufacturing/production?

14. What are the total costs involved in isobutanol manufacturing/production?

15. What are the future prospects and outlook of the isobutanol market?

16. What are project economics?

17. What are the profit margins?

18. What are the isobutanol pricing trends?

In case you have any specific business requirements, you can mention the same. We can customize the report based on your needs.

Related Reports:

Nylon Production Cost Analysis

Praseodymium Production Cost Analysis

Siloxanes Production Cost Analysis

Tetrahydro-linalool Production Cost Analysis

Lactose Production Cost Analysis

Glycine Production Cost Analysis

Why Choose Syndicated Analytics Reports:

- Our reports offer valuable insights for stakeholders to make informed business decisions and determine the feasibility of a business venture.

- With a vast network of consultants and domain experts in over 100 countries spanning North America, Europe, Asia Pacific, South America, Africa, and the Middle East, we provide in-depth market analysis and competitive intelligence.

- Our extensive database of equipment and raw material suppliers across major continents, combined with our ongoing tracking and updates of costs of land, construction, utilities, and labor across 100+ countries, provide valuable information for decision-making.

- As a trusted business partner to leading corporations, governments, and institutions worldwide, our client list ranges from small and start-up businesses to Fortune 500 companies.

- Our dedicated in-house team of experts, including engineers, statisticians, modeling experts, charted accountants, architects, and more, have a proven track record of building, expanding, and optimizing sustainable manufacturing plants globally.

About Us: Syndicated Analytics, a subsidiary of IMARC Group, offers consulting services and provides comprehensive market intelligence in the form of research reports, production cost reports, and feasibility studies. Our team, consisting of experienced researchers and analysts from diverse industries, is deeply committed to the quality of the information and insights delivered to the clients, which range from small and medium enterprises to Fortune 1000 companies. These firms are able to achieve this by studying the qualitative and quantitative aspects of the market as well as staying up-to-date with the current and evolving trends of the industry.

Contact Info:

Katherine Shields

Senior Sales & Marketing Manager

134 N 4th St. Brooklyn

NY 11249, USA

Phone No.: +1-213-316-7435

Website: https://www.syndicatedanalytics.com/

Email Address: sales@syndicatedanalytics.com