In today's era of focusing on environmental protection and sustainable development, wood pellets, as a clean and renewable biomass fuel, are gradually gaining widespread attention and application. Not only do they provide an affordable heating and cooking solution for homes, farms and small businesses, but they also greatly contribute to the resourceful use of waste. If you are considering venturing into this area, or wish to improve the efficiency of your existing wood pellet production, this article will provide you with a range of valuable advice and expert guidance.

The production process for wood pellets mainly consists of crushing, mixing (optional), drying, pelletizing, cooling (optional), screening, weighing and packaging. However, for small wood pellet plants, certain steps can be simplified due to the relatively small scale of production and the fact that they are often operated in family backyards, farms or small workshops with limited resources. For example, wood chippers, coolers and packaging machines are not essential equipment, but can be flexibly configured according to actual needs.

Key equipment and process optimization

Crushing systems, drying equipment and pellet mills are the three essential centerpieces in the production of small wood pellets. The crushing system is responsible for crushing the raw material to a suitable size (usually less than 3 mm) to ensure a smooth pelletizing process. The drying equipment is used to adjust the moisture content of the raw material, which is a key factor in the quality of the pellets. The pellet mill is the most important part of the whole production process, and its capacity directly determines the total output of wood pellets.

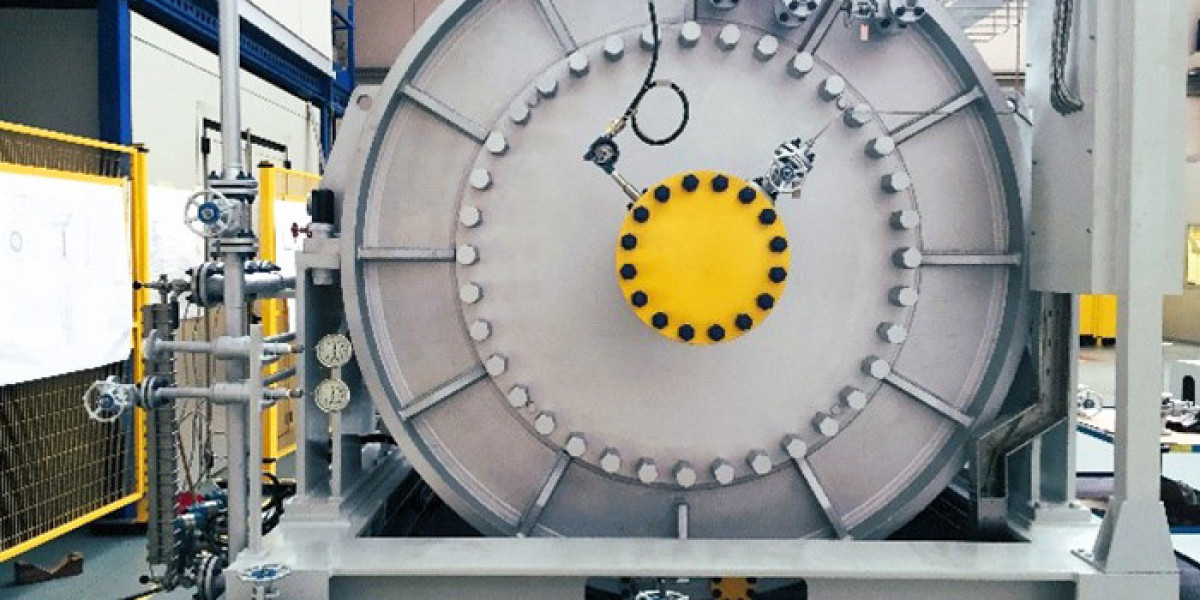

To meet the needs of our customers, we offer a wide range of customized equipment packages, from basic crushers and small wood pellet mills, to complete production lines with dryers, mixers, coolers and weighing and packaging machines. These machines are carefully designed and rigorously tested to ensure efficient and stable production performance.

These combinations of wood pellet machine are primarily designed to meet the needs of customers who want to make wood pellets in their own backyards, farms, small workshops, and more. If you have a business plan for the wood pellet manufacturing industry, then a large wood pellet plant with a complete wood pellet process is perfect for you. We can customize the process of small scale wood pellet manufacturing for you as per our requirements and conditions.

Significant advantages of homemade wood pellets

Homemade wood pellets not only help to solve the problem of waste accumulation, but also significantly reduce fuel costs. Compared to wood pellets that are mass-produced in large industrial plants on the market, homemade pellets can be sold at a more competitive price because you can utilize waste directly as a raw material, avoiding intermediate costs and profit mark-ups. In addition, homemade wood pellets can fulfill your family's daily fuel needs for heating and cooking, and can even be sold in the local market, providing you with an additional source of income.