Introduction

Octane is a critical component of gasoline that measures the fuel's ability to resist knocking during combustion. Higher octane ratings generally lead to better engine performance, efficiency, and lower emissions. Establishing an octane manufacturing plant is a strategic investment, driven by increasing fuel demands and advancements in automotive technologies. This Octane Manufacturing Plant Project Report explores the key aspects of setting up an octane manufacturing facility, including market analysis, project feasibility, raw material sourcing, manufacturing processes, and financial projections.

Market Analysis

Demand and Supply

The global demand for octane is primarily influenced by the automotive industry, which is experiencing a shift towards more efficient and environmentally friendly fuels. As countries implement stricter emission regulations and consumers demand higher performance from their vehicles, the need for high-octane fuels is expected to rise. Additionally, the expansion of hybrid and electric vehicles may create opportunities for octane-based fuel additives.

Target Market

The target market for octane production includes:

- Refineries: As a blending component in gasoline formulations.

- Chemical Manufacturers: For the production of solvents and other chemicals.

- Additive Suppliers: As a base for various fuel additives and performance enhancers.

Competition

The octane market is competitive, with several established players already in the field. However, innovations in production technology and a focus on sustainable practices can provide new entrants with a competitive advantage.

Get a Free Sample Report with Table of Contents @

Project Feasibility

Location

Selecting a suitable location for the manufacturing plant is crucial. Ideal factors include:

- Proximity to raw material suppliers (such as petroleum products).

- Access to transportation networks (roads, railways, ports).

- Availability of utilities (water, electricity, and gas).

- Access to target markets to minimize distribution costs.

Technology

The production of octane typically involves refining processes, including catalytic reforming and isomerization. The choice of technology will depend on the desired octane rating, production capacity, and cost efficiency.

Regulatory Compliance

Compliance with environmental regulations and safety standards is essential for the operation of an octane manufacturing facility. It’s vital to obtain all necessary licenses and permits before commencing operations.

Raw Material Sourcing

The primary raw materials for octane production include:

- Crude Oil: The main feedstock, which undergoes various refining processes to produce high-octane products.

- Natural Gas: Sometimes used in the production of certain octane-enhancing components.

- Additives: Various chemicals can be used to boost octane levels, such as ethanol and alkylate.

Building strong relationships with reliable suppliers will ensure the consistency and quality of raw materials.

Manufacturing Process

Overview

The octane manufacturing process typically involves several key steps:

- Crude Oil Distillation: Separating crude oil into different fractions based on boiling points.

- Catalytic Reforming: Converting low-octane naphtha into high-octane products through chemical reactions.

- Isomerization: Rearranging the molecular structure of hydrocarbons to enhance octane ratings.

- Additive Blending: Mixing octane boosters and other additives to achieve the desired fuel properties.

- Quality Control: Testing the final product for compliance with industry standards.

Quality Assurance

Implementing a robust quality assurance system is crucial to ensure that the final octane product meets the required specifications. Regular testing for octane ratings, impurities, and other chemical properties should be conducted.

Financial Projections

Capital Investment

The initial capital investment required to establish an octane manufacturing plant can vary widely depending on the scale of operations, technology employed, and location. A medium-sized facility may require an investment ranging from $2 million to $10 million.

Operating Costs

Key operating costs include:

- Raw materials (crude oil and additives)

- Labor

- Utilities (water, electricity, gas)

- Maintenance

- Marketing and distribution

Revenue Projections

With an effective marketing strategy and pricing approach, an octane manufacturing plant can achieve a break-even point within 3-5 years. Profit margins typically range from 8% to 15%, depending on market conditions and operational efficiency.

FAQs

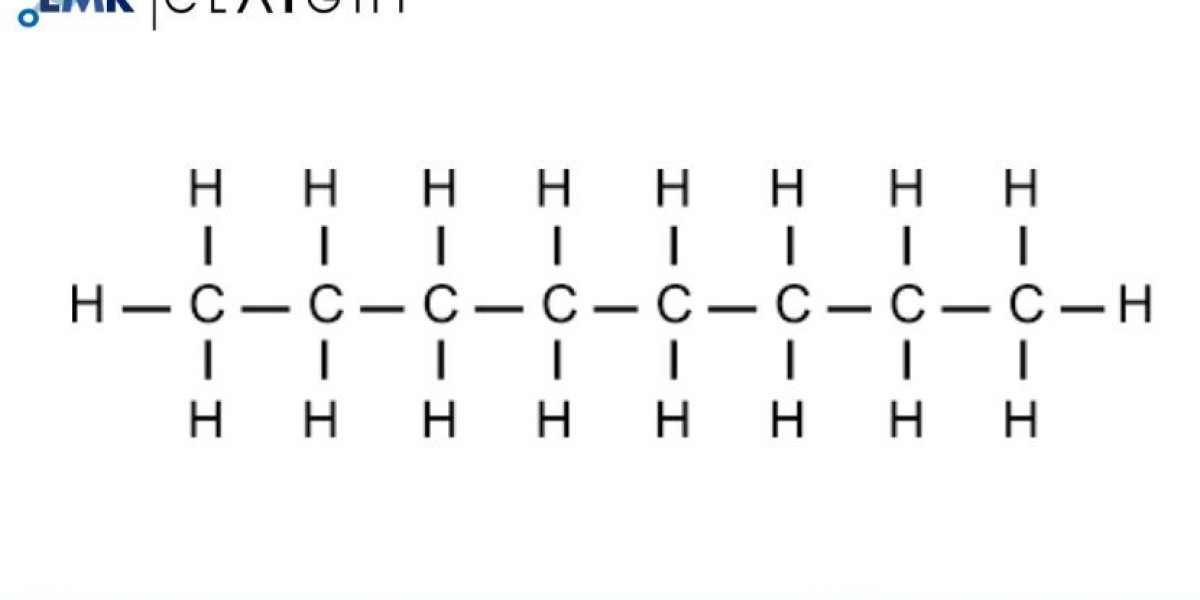

1. What is octane, and why is it important?

Octane is a measure of a fuel's ability to resist knocking or pinging during combustion. Higher octane ratings indicate better performance and efficiency in engines, making octane a crucial component of gasoline.

2. What technologies are used in octane production?

Common technologies include catalytic reforming and isomerization, which convert low-octane hydrocarbons into higher-octane fuels through chemical processes.

3. How do environmental regulations impact octane manufacturing?

Manufacturers must comply with local and international environmental regulations regarding emissions and waste management. These regulations can affect production processes, costs, and operational practices.

4. What are the primary raw materials for producing octane?

The primary raw materials are crude oil, natural gas, and various chemical additives used to enhance octane levels.

5. What are the financial risks associated with starting an octane manufacturing plant?

Financial risks include fluctuations in crude oil prices, regulatory changes, competition in the market, and potential operational challenges. Conducting thorough market research and financial forecasting can help mitigate these risks.

Related Reports

https://www.expertmarketresearch.com/reports/spain-residential-real-estate-market

https://www.expertmarketresearch.com/reports/remote-sensing-software-market

https://www.expertmarketresearch.com/articles/top-plywood-companies

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au