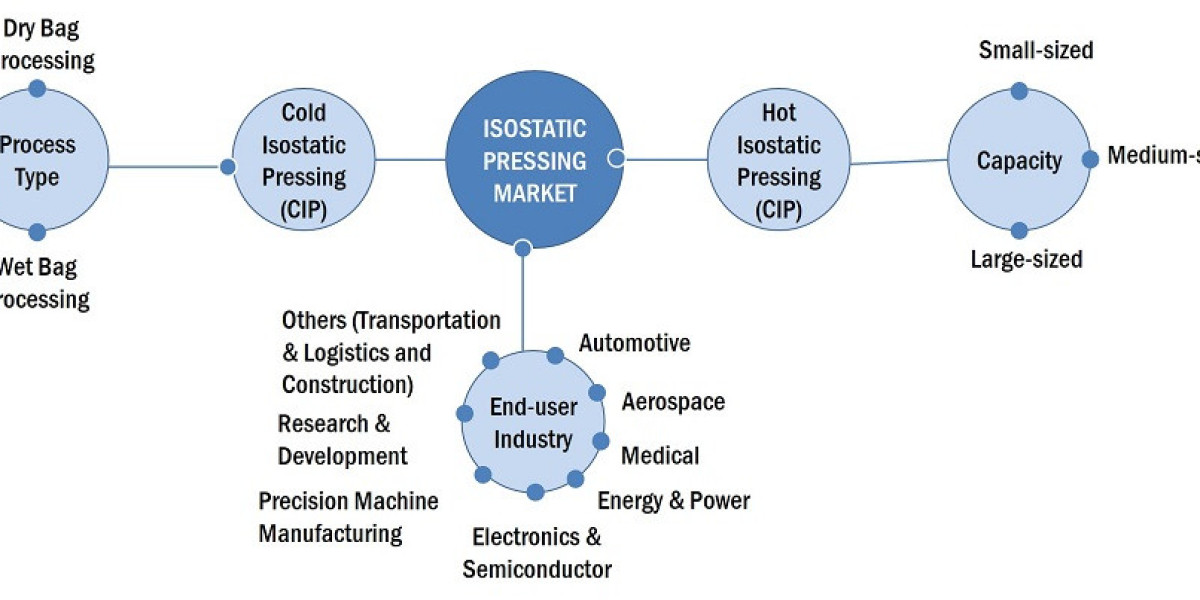

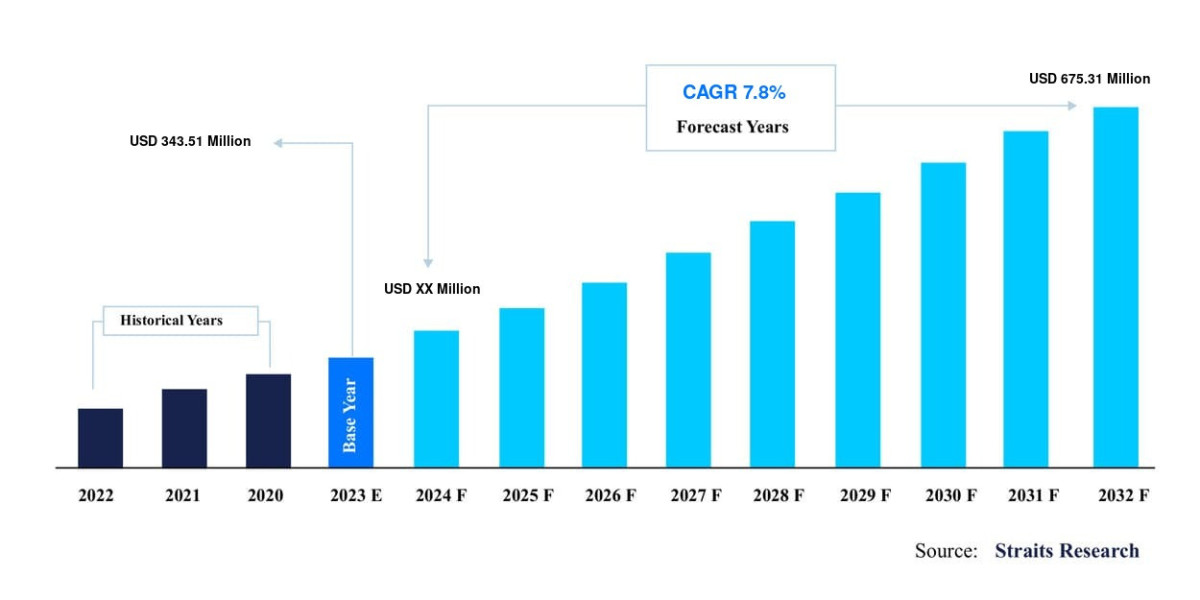

The global isostatic pressing market is forecast to reach USD 9.9 billion by 2029, growing from USD 7.6 billion in 2024, at a CAGR of 5.4%. The market’s growth is driven by several factors, including the increasing use of Hot Isostatic Pressing (HIP) systems for densifying 3D-printed parts, technological advancements in Cold Isostatic Pressing (CIP), and the growing demand for high-density materials across industries like aerospace, automotive, and medical.

HIP Systems Play Key Role in Market Growth

Hot Isostatic Pressing (HIP) is expected to witness strong growth as industries seek to improve the mechanical properties of their components. HIP is widely used in powder metallurgy and the production of complex parts like valves, pipes, and rods. The demand for HIP systems is particularly strong in the aerospace and defense sectors, where materials must meet high-performance standards. HIP’s ability to increase density and reduce porosity in 3D-printed parts also makes it a valuable tool in the additive manufacturing industry.

Service Segment to Record Highest CAGR

The service segment, encompassing HIP/CIP cladding, casting densification, and powder compacting, is set to grow at the highest CAGR during the forecast period. As industries place greater emphasis on material reliability and longevity, isostatic pressing services are becoming increasingly important. Companies like Bodycote and MTC Powder Solutions lead the market in offering high-quality services that meet the demanding specifications of the aerospace, medical, and automotive industries.

Dry Bag Pressing Outpaces Wet Bag Pressing

In the cold isostatic pressing market, dry bag pressing systems dominate due to their efficiency and speed. Dry bag systems are fully automated and feature computerized controls, which streamline the production process and reduce operating costs. As a result, dry bag pressing has become the preferred method for mass production, further solidifying its market position.

Precision Machine Manufacturing Sector Leads

The precision machine manufacturing industry holds the largest market share, driven by the use of HIP in producing machinery parts and heavy equipment. This sector benefits from the high-quality output that HIP systems provide, particularly in the manufacture of aluminum castings. Other industries, such as energy & power, oil & gas, and food & beverage, are also contributing to the growth of the precision machine manufacturing segment, as they adopt isostatic pressing technologies to improve the durability and performance of their products.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=23702585

North America Leads Isostatic Pressing Market

North America is the leading region in the global isostatic pressing market, with a large share driven by demand from industries such as aerospace, defense, and automotive. The region is home to several key industry players, including Bodycote, which operates advanced HIP systems to improve the quality of industrial components by eliminating porosity. The growing demand for high-performance materials in the region’s manufacturing sectors is expected to sustain North America’s leadership in the market throughout the forecast period.