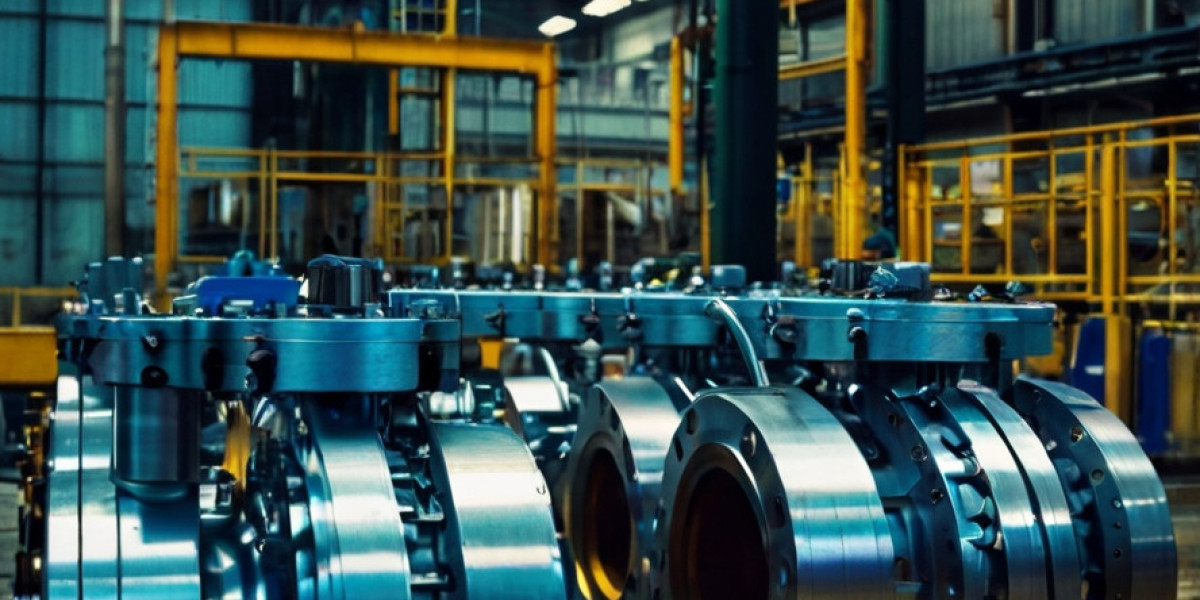

The ball valves market involves mechanical devices used to control fluid flow in pipelines. It features a spherical closure element that rotates in a casing to manage the flow. The market addresses the needs of diverse industries. That includes water treatment, chemical processing, and other sectors. All of these need accurate fluid management. Industrialization and the need for efficient fluid handling in multiple industries are key factors driving the need for ball valves.

In the gas and oil sector ball valves are essential for regulating the crude oil flow and various fluids across drilling rigs or petrochemical facilities. It happens both offshore and onshore. In water treatment facilities ball valves are essential for managing the flow of both chemicals and water throughout different procedures. The chemical sector relies on ball valves to control the flow of hazardous and caustic chemicals. In HVAC, power production facilities, along with municipal infrastructure also use them for managing fluid flow.

Ball valves come in multiple designs from manufacturers. That includes floating and top-entry models. Each configuration suited to particular pressure and flow conditions. The construction materials for ball valves include stainless steel and advanced alloys. That includes Hastelloy and titanium. They provide compatibility with various fluids and operational conditions.

What Drives the Market?

The ball valves market size expansion has been growing rapidly in recent years across the world. There are several drivers that boost this market expansion.

1. Industrial development

Ball valves are in high demand due to the expanding industrial sectors. That includes water treatment and chemicals. There are also infrastructure development initiatives across the globe where the valves are crucial for fluid control.

2. Enhancements in technology

The market is being propelled by ongoing advancements in valve technology. That includes innovations in design and automation. Manufacturers strive to boost the ball valves’ performance and longevity to address the evolving demands of various industries.

3. Water treatment expansion

The rising global priority on water conservation and environmental concern is boosting investments in water treatment infrastructure. The valves are essential in these systems for managing the water flow and sludge. This further fosters the sector’s expansion.

4. Oil exploration

Even though renewable energy is gaining attention, gas and oil remain the primary global energy sources. Ball valves are essential in drilling rigs and refineries for the exploration or extraction of oil. Therefore, it drives market growth.

5. Reduce cost and improve efficiency

To maintain competitiveness industries are focusing on boosting operational efficiency and cutting costs. Ball valves are increasingly preferred due to their low maintenance demands, reliable performance, and durability. This makes them ideal for companies looking to manage their budgets effectively.

The Challenges

However, the ball valves market also faces several challenges.

1. Rising competition

The market faces competition from alternative technologies. That includes gate and globe valves. These competing options can provide comparable functionality in specific situations. It potentially impacts the sector growth.

2. Raw materials price

Another challenge in the ball valves market is in terms of raw materials prices. Volatility in the prices of raw materials like stainless steel affects the production costs. Manufacturing companies may struggle to keep prices competitive due to these variable material costs. This can undermine market stability.