In the world of machinery, safety and reliability are of utmost importance. One crucial aspect that contributes to these factors is the use of custom fasteners. Custom fasteners are designed and manufactured to meet the specific requirements of a particular application, providing a tailored solution that can enhance machine safety and reliability. In this article, we will explore the role of custom fasteners in enhancing machine safety and reliability.

The Importance of Machine Safety

Machine safety is a critical aspect of any industrial operation. Machines that are not properly secured can pose a significant risk to operators, maintenance personnel, and other individuals in the surrounding area. In addition, machine failure can also result in costly downtime, damage to equipment, and loss of productivity. Custom fasteners play a vital role in ensuring machine safety by providing a secure and reliable connection between components. By using custom fasteners, manufacturers can reduce the risk of accidents and injuries, while also minimizing the risk of machine failure.

The Role of Custom Fasteners in Enhancing Machine Reliability

Machine reliability is also a critical aspect of industrial operations. Machines that are not reliable can result in costly downtime, reduced productivity, and increased maintenance costs. custom machine fasteners can enhance machine reliability by providing a secure and consistent connection between components. By using custom fasteners, manufacturers can reduce the risk of machine failure, while also minimizing the need for frequent maintenance and repairs. Additionally, custom fasteners can also improve the overall performance of machines, by reducing vibration, noise, and other forms of wear and tear.

Designing Custom Fasteners for Machine Safety and Reliability

Designing custom fasteners for machine safety and reliability requires a deep understanding of the specific requirements of the application. This includes considering factors such as operating temperature, pressure, and vibration, as well as the required strength, durability, and corrosion resistance of the fastener. The design process typically begins with a thorough analysis of the application, including the use of computer-aided design (CAD) software and finite element analysis (FEA) to simulate the behavior of the fastener under various loads and conditions. Prototypes are then manufactured and tested to validate the design, and any necessary modifications are made before production.

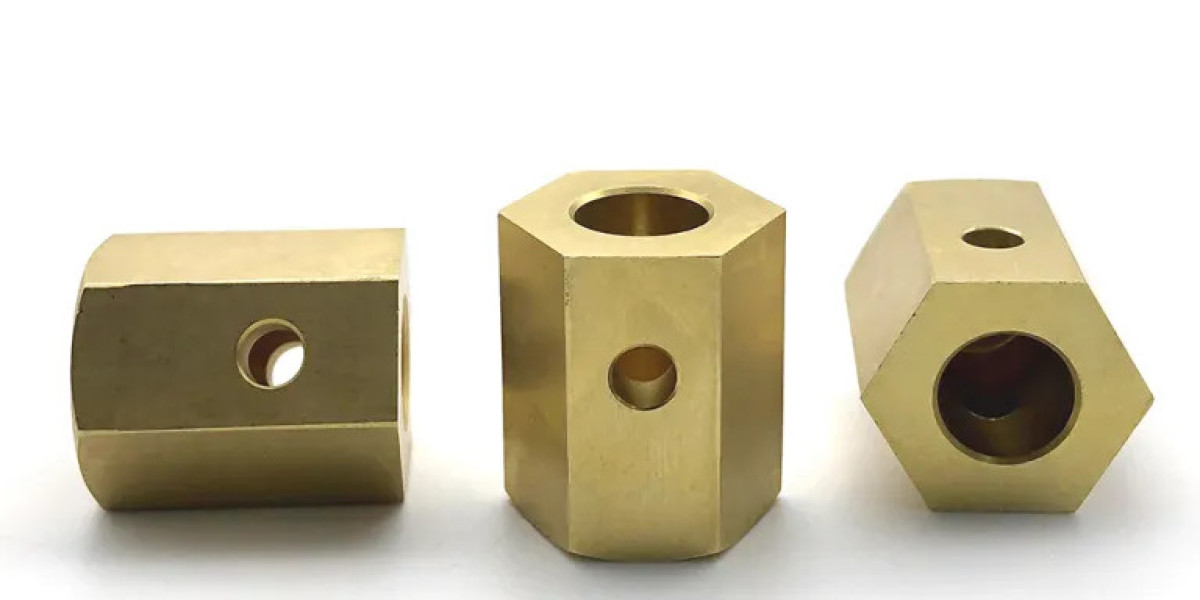

Materials and Manufacturing

Custom fasteners for machine safety and reliability can be manufactured from a wide range of materials, including metals, such as stainless steel, titanium, and aluminum, as well as advanced polymers and composites. The choice of material depends on the specific requirements of the application, including strength, durability, and corrosion resistance. Modern manufacturing techniques, such as 3D printing and CNC machining, enable the production of complex geometries and custom shapes, which can improve the performance and efficiency of the fastener. Additionally, surface treatments, such as coatings and platings, can be applied to enhance the corrosion resistance and wear properties of the fastener.

Industry Examples and Case Studies

There are several examples of how custom fasteners have been used to enhance machine safety and reliability. In the aerospace industry, custom fasteners have been used to secure critical components, such as engine mounts and fuel tanks, where failure is not an option. In the automotive industry, custom fasteners have been used to secure components, such as engine blocks and gearboxes, where high strength and durability are required. In the energy industry, custom fasteners have been used to secure components, such as wind turbine blades and pipeline connectors, where high strength and corrosion resistance are critical.

Conclusion

In conclusion, custom fasteners play a critical role in enhancing machine safety and reliability. By providing a tailored solution, custom fasteners can reduce the risk of accidents and injuries, while also minimizing the risk of machine failure. Whether it's in the aerospace, automotive, energy, or construction industry, custom fasteners can provide a critical advantage in machine safety and reliability. By investing in custom fasteners, manufacturers can reap the benefits of improved safety, reliability, and productivity, while also reducing costs and minimizing the risk of accidents and injuries.